Blistering Paint, Cracking Paint and Other Paint Defects and Solutions

Painting not only gives a good appearance to a structure but also protects against corrosion, decaying, weathering, and other environmental conditions. Without the correct choice of paint, sufficient surface preparation, or proper paint application, numerous paint problems can occur. From poor adhesion to poor finish, knowing why paint fails is the best way to ensure a long-lasting, problem-free paint job. Understanding the cause and solutions for these common paint problems will help to address them quickly and avoid them in the future.

This article will examine the most common paint problems and their solutions.

Paint Defects Caused by Poor Adhesion

Most adhesion issues are caused by improper surface preparation, insufficient priming, inferior quality paint, or improper application. Surface preparation is a critical process to ensure efficient adherence of a coating to its substrate. Coating performance is determined by the coating's ability to adhere to the substrate material. Surface preparation removes uncontrolled impurities or contamination like mill scale and grease.

Before coating you should first assess the surface by following international standards. Then clean the surface chemically or mechanically to remove loose particles, pre-existing layers, surface defects, organic matter, oxidation, and other pollutants from the surface. Dry the surface and profile the surface characteristics. New coatings may require a different surface profile than the previous. The surface needs to be cleaned, repaired, patched, masked and primed to be durable and create a long lasting bond. Always use a high quality paint and follow the manufacturers recommendations for proper application.

-

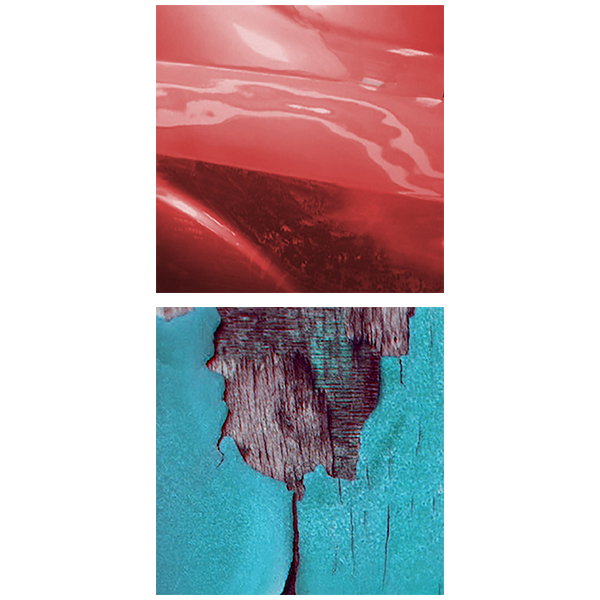

Feather Edge Lifting / Edge Mapping is when solvents in topcoats penetrate through areas of the undercoat and causes

the film edges to peel or lift from the paint. This can be caused from dirt and debris getting trapped under the film,

temperature changes, wear or improper cleaning.

Solution: Use a good primer on the surface that is water-based, two-component or use another sealer to create a good barrier layer. -

Flaking Paint is the detachment of paint from the surface of the substrate. It occurs when the bond between the paint film and surface

is poor.

Solution: Proper surface preparation is necessary for good adhesion. Test and clean the surface prior to painting. Eliminate any surface contamination, wood rot, chalkiness or rust by sanding, repairing, cleaning and re-painting.

-

Blistering Paint is a paint defect where swelling of the paint film occurs by the formation of an air bubble under the paint due to moisture, oil or grease. These defects are commonly seen on wood siding and trim. If the defect is due is due to oil and grease it is called blistering.

Solution: If the defects go all the way to the substrate, remove the source of moisture and scrape away the paint blisters. Prime and repaint with acrylic latex. If the defects do not go all the way to the substrate, scrape or sand them away and repaint without priming. -

Peeling Paint is a paint defect where formation of an air bubble occurs under the paint due to moisture, oil or grease. These defects are commonly seen on wood siding and trim. If the defect is due to moisture, then it is called peeling.

Solution: If the defects go all the way to the substrate, remove the source of moisture and scrape away the peeling paint and blisters. Prime and repaint with acrylic latex. If the defects do not go all the way to the substrate, scrape or sand them away and repaint without priming.

-

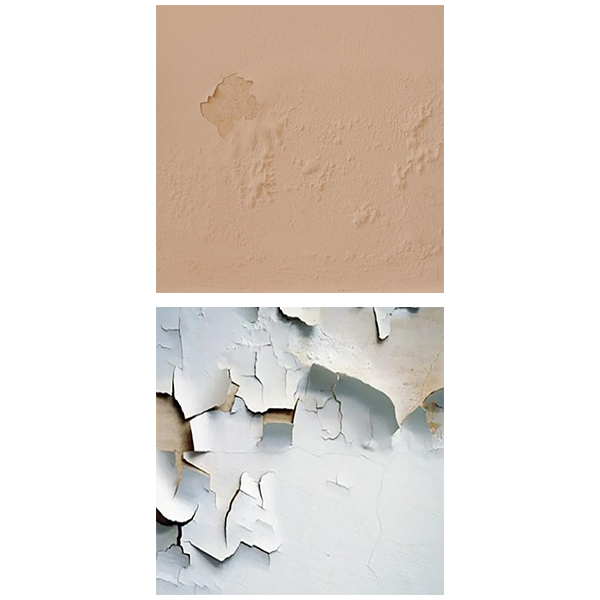

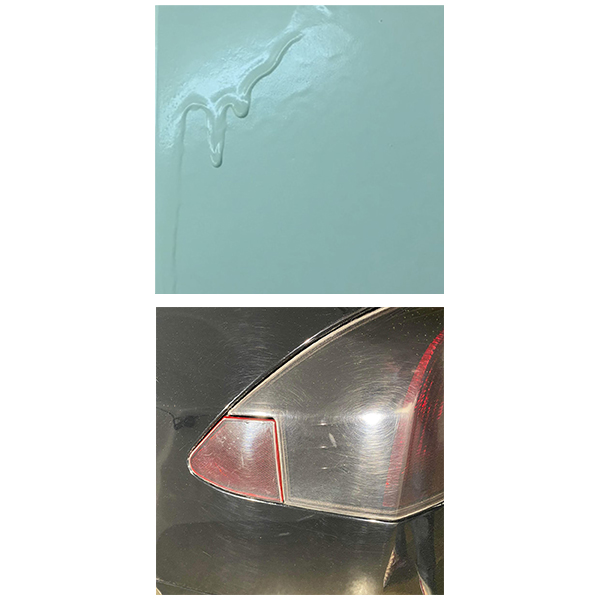

Wrinkling Paint (urethanes and enamels) Usually occurs when applying a second coat of

paint prior to the first coat drying. Solvents in the wet paint underneath break down the second coat when they

try to pass through it and make it wrinkle.

Solution: Strip the paint with a chemical stripper or heat and repaint allowing the undercoat sufficient time to dry completely prior to the application of the final coat. -

Chipping Paint is when the paint begins to separate from the substrate by peeling and

breaking off into small pieces.

Solution: Remove all loose paint chips from effected area with wire brush or paint scraper. Be sure not to use too much pressure which can damage the surface area underneath.

Paint Defects Caused by Poor Finish - Surface Texture

Poor surface finishes are normally caused by application during poor environmental conditions, are unsightly and can cause coatings to be more difficult to adhere. This leads to pockets of uncoated substrate where corrosion can form in or on the uncoated area. Poor surface finishes have a detrimental effect on corrosion resistance and can make processes like painting, more difficult and time-consuming. Surface texture can also lead to more friction effects between the part and other objects, as well as decreased strength and wear resistance. Below you will find the most common surface texture defects from an improper finish and their solutions.

-

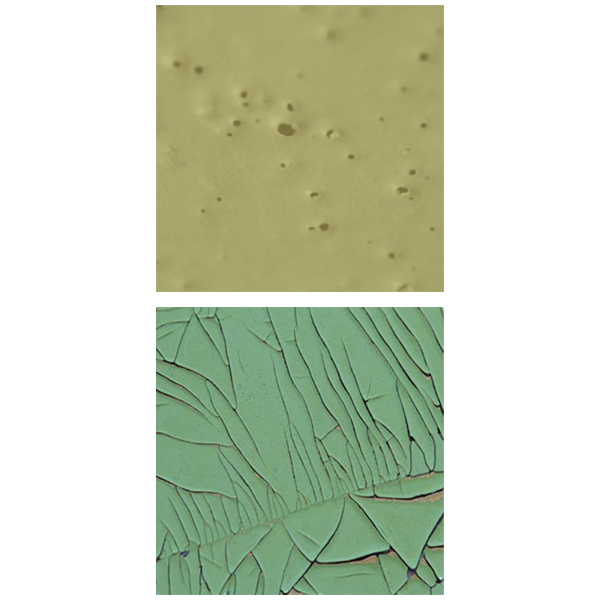

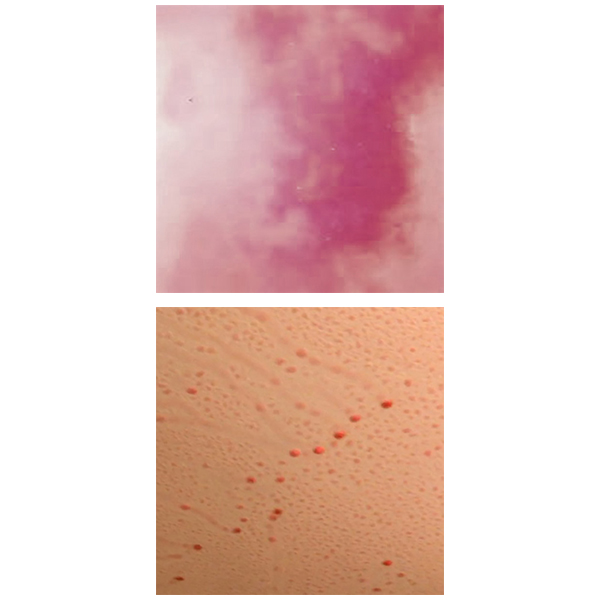

Pinholes in paint are small blisters that emerge as moisture evaporates between the surface and the coating during the curing

process. Pinholes are often caused by trapped air, trapped solvents and trapped moisture escaping from the film.

Moisture can affect drying times, even if some coatings use a second layer to cover these pinholes.

Solution: Make sure surfaces to be coated are fully cleaned and degreased before application. Take great care to avoid moisture on the surface. Use correct gun pressure, technique and gun adjustments. -

Cracking Paint is the splitting of paint from use of inferior quality paint, lack of surface prep, failing to prime, paint with inadequate adhesion and flexibility, overthinning or overspreading, or hardness and brittleness of aged paint. It starts

as a hairline crack and progresses to flaking.

Solution: Sand, scrape or wire brush away loose paint. Sand any hard edges, and prime bare areas then repaint. Use a high-quality paint and primer to prevent recurrence.

-

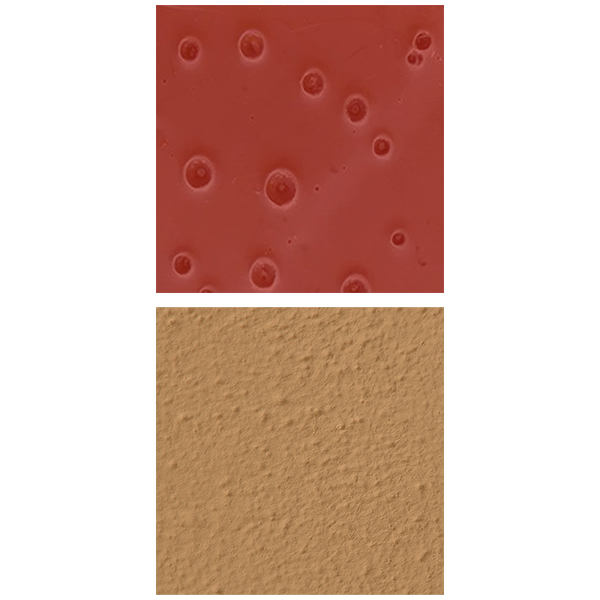

Fisheyes in paint are when small craters form in the wet film or topcoat or where spots of an undercoating shows through.

Fisheyes are normally caused by painting over contaminated surfaces; by using a thinner in place of a solvent cleaner;

or re-spraying previously repaired areas containing "fisheye eliminator" additive.

Solution: In a basecoat, if fisheyes appear allow the paint to dry then spray a mist coat over affected area. Do not use fisheye eliminator in undercoats or basecoats. -

Orange Peel in paint is when hills and valleys in the paint form a texture resembling the skin of an orange. It is normally caused by paint being too thick; spray gun being too close; solvent evaporating too fast; or air pressure being too low.

Solution: Sand away affected area, sand and blend edges, then clean and prime the surface and repaint. Avoid too-thin or too-thick of an application.

-

Sags in paint are an excess flow of paint from the spray gun being too close, too much paint on the roller or brush, too much

thinner in the paint or the surface being too cold, hard or glossy for application.

Solution: Before curing, brush out the excess paint or wash with a solvent and adjust the spray gun. Sand the area, blend the edges and re-apply another application of paint. Avoid too-thin or too-thick of an application. -

Softness occurs when the paint does not harden in the designated drying time. This is normally caused by contaminated softening agents, excessive storage time, excessive film builds or insufficient cure time.

Solution: Remove all affected paint with a scraper, wire brush, heat gun, or chemicals. Sand, blend the edges, then clean and prime the surface and repaint. Avoid too-thin or too-thick of an application.

-

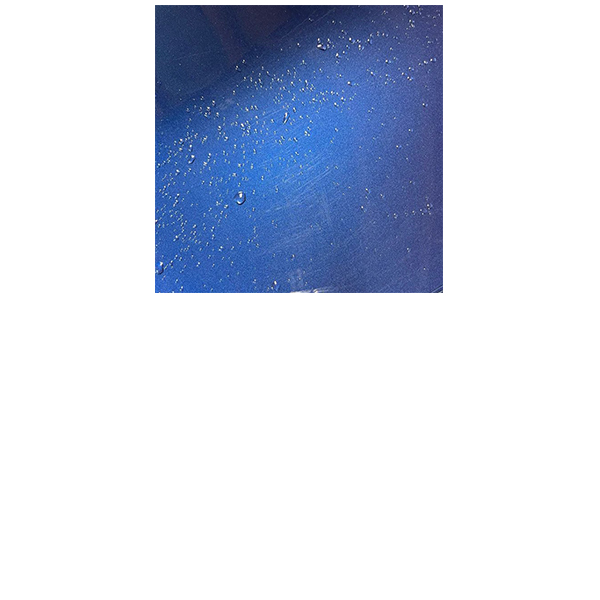

Static in paint is a charge produced by friction from sanding, wiping, tacking, blowing off, masking and application of

materials. Static builds up is a major cause of paint contamination, inconsistent and uneven application of metallics,

improper color matching, and patchiness.

Solution: Use ionized air throughout the painting process. Static forms in a positive and negative charge, so a tool that produces positive and negative ions to neutralize the charge is needed. Positive neutralizes the negative and negative neutralizes the positive.

Paint Defects Caused by Poor Finish - Color

A paint finish defines the final look of the piece being coated. The key to choosing the right paint finish is a balance between aesthetic, durability, and cleanability. A poor paint finish can bring about many problematic issues with the piece's color. The finish can discolor, fade, frost, blush, or bleed through the topcoat Dirt and contamination can also cause small bumps in, on, or under the paint that can change the appearance of the color. Below you will find the most common color defects from an improper finish and their solutions.

-

Blushing Paint is the dull cloudy haze from moisture trapped in the paint layer. It appears when the solvent quickly evaporates from a drop in temperature condensing the water in the air. Other causes include temperature being below 60 °F or above 95 °F

during application, using incorrect reducer or using too high of air pressure while spraying.

Solution: During application add a slow drying retarder to the paint mixture and re-coat the area. If found after the finish has dried the surface must be sanded and repainted. -

Paint Bleeding is the discoloration of the paint surface of the color due to new paint penetrating and dissolving the old coating and releasing the dye to the surface. This action is often referred to as bleeding through.

Solution: Remove all of the paint in the area by scraping, sanding or with a solvent; allow the surface to completely dry; apply sealer and refinish.

-

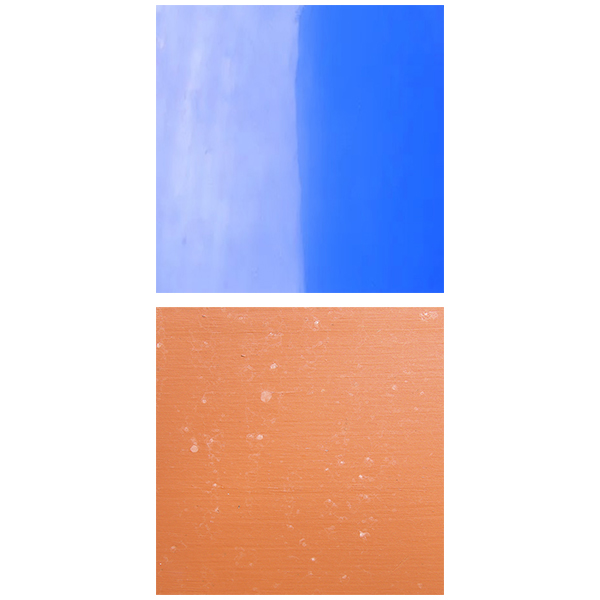

Fading Paint is discoloration of the paint surface due to environmental conditions such as rain, sunlight, moisture or temperature variations. Use of dark paints, inadequate film thickness or inferior quality paint are also plausible reasons for fading.

Solution: Use light colored, weather resistant, quality pigments. Once fading begins, it cannot be repaired completely, but weathering-resistant pigments may be used to prevent further discoloration. -

Frosting Paint is the occurrence of a white salt-like substance on the paint surface due to the use of calcium-carbonate fillers. The filler causing the issue could either be in the dark paint or contained in the primer layer being painted over.

Solution: Remove the frosting from the painted wood surface by sanding the area or from masonry with a wire brush. Rinse the surface area thoroughly and let dry. Then prime with an alkyd-based primer and topcoat with a high-quality exterior paint.

-

Grinning Paint is when a material's underlying surface shows through the coating due to insufficient coating thickness of paint on the substrate, insufficient hiding power, or from burst air bubbles that formed on the paint's surface. The paint film should be opaque enough to cover the background surface.

Solution: First be sure you are using a high quality paint with good opacity. Use a tinted primer if painting a surface significantly darker than the new paint. Then be sure to apply an adequate amount of coating between individual coats of the primer and paint. -

Paint Discoloration is the process in which a coating applied to a surface changes color due to sunlight, air pollution, humidity, other environmental conditions, or when the solvent in the topcoat dissolves soluble pigments in the old finish below.

Solution: Remove defects by scraping, sanding, applying chemical removers, or by using a heat gun. Then rinse to remove dust and let dry completely. Prime, allow to dry and repaint.

-

Dulling Paint or Dieback is when the gloss on the paint finish becomes dull from dryness aging or wear; thinners are improperly used; the surface is not properly primed, or the undercoat is not given sufficient drying time. It can also appear where the topcoat is applied in damp conditions.

Solution: Allow the paint to completely dry, then rub down or lightly sand the area with fine sandpaper. Take particular care to blend the edges and correct the consistency of coating. Dust off all loose particles and apply a new topcoat. -

Paint Fogging is when the finish fogs up from the substrate or paint being too cold during application. The spray area and the spray paint must be at least room temperature.

Solution: Do not spray the finish if your work area is colder than room temperature. In cold weather, use a suitable heat source to raise the temperature to at least room temperature.

-

Paint Mottling is where the metallic in metallic coatings gathers together in areas giving an uneven, blotchy or streaky appearance. It is usually caused by the base coat being too wet resulting in the metallic flakes bunching together.

Solution: Spray your base coat with medium wet coats. You are spraying too wet. Ways to spray a medium wet coat include decreasing fluid, moving faster, or holding the gun further from the surface being painted. - Sand scratches are lines or streaks that can be seen through the paint from sanding with an abrasive that is too coarse, improper sanding technique, undercoat with insufficient drying time, or too thin of a topcoat. Always Follow Manufacturer's recommendations for correct preparation methods, drying times and application. Use a guide coat when sanding.

Solution: Sand, clean and refinish using recommendations.

-

Chalking is when a powder forms on the painted surface from wearing away of the paint film by weathering, insufficient oil in the

primer or from salts rising to the surface.

Solution: Brush down the substrate with a stiff bristle brush to remove as much of the powder as possible before applying a coat of primer.

To Avoid These Paint Defects

-

Consider Your Selection Of Paint:

Paint should be selected based on type of surface, the type of environment, weather resistance, durability, color duration as well as other factors that affect the quality of the paint. The paint quality itself is directly related to its additives. These additives are comprised of rheology modifiers which help with proper paint application, dispersants for proper coverage, biocides to prevent bacteria from forming, mildewcides to prevent mold from growing and defoamers that break down bubbles caused by stirring and shaking.

-

Ensure Proper Surface:

Surface preparation ensures that a substrate is ready to receive a coating, be adhered to another material or other common surface applications. A dirty or compromised surface can reduce the effectiveness of a new coating, cause adhesion failure or otherwise undermine a process. Surface preparation works to ensure the best adhesion, mechanical bonding, or weld quality, as well as preventing future corrosion and mechanical damage.

-

Ensure Proper Paint Application:

- Proper choice of paint

- Proper environment for painting

- Proper painting tools

- Cleaning of dirty tools

- Proper surface cleaning and preparation

- Following the manufacturer's technical data sheet (TDS)

- Proper method of application

- Proper calculation of paint drying time

-

Follow up with Proper Testing and Maintenance:

All paint projects should be routinely monitored, tested and maintained. To ensure the performance of the coating over time, mechanical or physical tests may be needed. Specific data on the properties of the coating should be monitored for maintenance.

Coatings are applied to improve the substrate's properties and to create a protective barrier against corrosion and deterioration of its surface. Most all paint and coatings defects can be avoided by following manufacturer's recommendations, proper surface preparation, testing and maintenance. If these defects do occur, refer back to the manufacturer's data sheet, identify the specific defect and proper corrective actions.