Troubleshooting Surface Appearance

Orange Peel and DOI Measurement

The surface appearance of coatings is paramount across numerous industries due to its significant impact on product quality, aesthetics, and consumer perception. Whether in automotive finishes, architectural coatings, or consumer goods like furniture, the surface appearance represents craftsmanship and attention to detail. A flawless surface enhances the product’s appeal and reflects superior quality and durability. However, even with meticulous application techniques, surface imperfections can occur.

Two key factors play a significant role in the appearance of surfaces - Orange Peel and DOI. However, to effectively troubleshoot surface appearance issues, we must first grasp how we perceive surfaces visually. Human perception alone is not sufficient to accurately make appearance judgments. The sample's total appearance must be considered to measure surface appearance accurately.

Total Appearance

Total appearance refers to the overall visual impression of a surface, considering multiple factors such as color, gloss, texture, uniformity, defects, and imperfections.

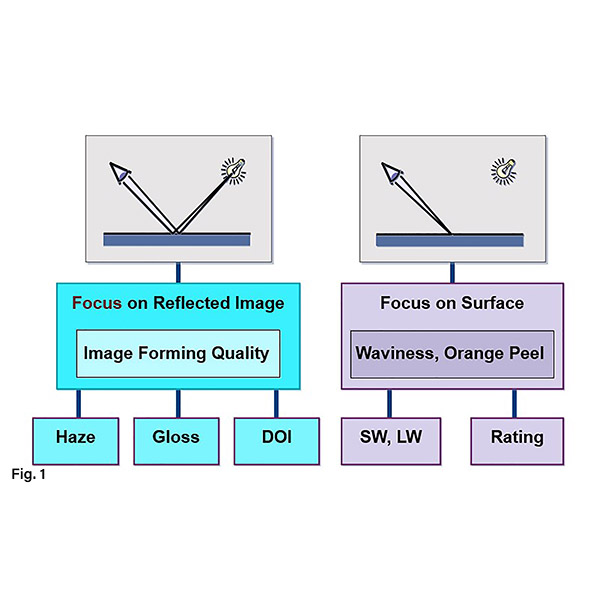

The evaluation of a surface entails focusing on either the reflected image of a light source or focusing directly on the surface itself

When examining the reflected image of a light source, consider its ability to form clear images, particularly its capacity to reflect objects. This reflection quality can range from bright to dull, often referred to as gloss. Furthermore, phenomena like the brightening of dark areas (haze) and fluctuations in edge sharpness or clarity (DOI) may become apparent when observing reflections along edges. (fig 2)

Focusing on the surface gives additional information about the structure size and form, seeing these structures as a wavy pattern of light and dark areas. This waviness is often called orange peel or flow/leveling defects. (Fig. 3)

Both evaluation methods are individually weighted and contribute to the total appearance perception. Appearance should be defined with objective and measurable criteria to guarantee reliable quality assurance. The total appearance and the visibility of structures depend on the structure size, the observing distance, and the image-forming quality.

Understanding and Troubleshooting Orange Peel:

Orange peel refers to a textured surface defect characterized by a rippled or dimpled appearance similar to the outer peel of an orange. It occurs due to irregularities in the coating film during application, drying, or curing processes.

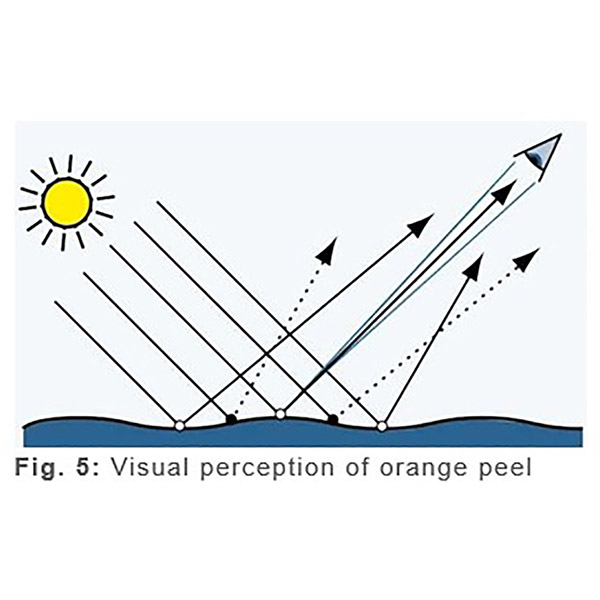

It can be seen on high-gloss surfaces as a wavy pattern of light and dark areas. Depending on the structure's slope, the light is reflected in various directions (Fig. 5). Only the elements reflecting the light in the direction of our eyes are perceived as light areas. Visibility of structures is dependent on the observing distance. The greater the distance, the smaller objects will appear, and less detail will be visible.

Various Factors that Contribute to Orange Peel:

- Viscosity:

Issue: Improper viscosity of the coating material can lead to uneven flow leveling, resulting in orange peel.

Solution: Ensure the coating material is mixed correctly and thinned according to manufacturer recommendations to achieve the desired viscosity for optimal flow and leveling. - Application Technique:

Issue: Incorrect spraying techniques, such as spraying too close or too far from the surface, improper gun settings, or inconsistent spraying patterns, can cause orange peel.

Solution: Train operators on proper spraying techniques, including maintaining consistent gun distance, angle, and speed, to achieve uniform coating application and minimize orange peel. - Environmental Conditions:

Issue: Factors like temperature, humidity, and airflow in the application environment can affect the drying and leveling of the coating, leading to orange peel.

Solution: Maintain ideal environmental conditions, such as temperature and humidity levels, and ensure proper airflow to facilitate adequate drying and leveling of the coating. - Substrate Preparation:

Issue: Poor surface preparation, such as inadequate cleaning, uneven sanding, or improper priming, can result in orange peel by creating inconsistencies in the coating adhesion and flow.

Solution: Implement thorough surface preparation procedures, including cleaning, sanding, and priming, to create a smooth and uniform substrate for optimal coating adhesion and flow. - Coating Properties:

Issue: The formulation of the coating material, including its composition, additives, and solvent content, can influence its flow and leveling characteristics, impacting the occurrence of orange peel.

Solution: Selecting Suitable Coating Materials: Choose coating materials with appropriate flow and leveling properties for the specific application and substrate, considering viscosity, solvent content, and additives.

Understanding and Troubleshooting DOI Measurement:

Distinctness of Image (DOI) measures the clarity and sharpness of reflections on a surface. It refers to the ability of a surface to reflect images accurately without distortion or interference. DOI can be measured by projecting light onto the surface at a preferred 20° angle. The reflected light is collected at an angle equal to but opposite to the standard, specular angle, using a wider angular measurement band. This determines the amount of light deflected away from the specular angle. High DOI means clear and sharp reflections, while low DOI appears blurry. DOI is particularly critical in glossy or high-end finishes, where visual clarity and depth perception are essential.

Factors affecting DOI Measurement include:

-

Surface Smoothness:

Issue: A rough surface typically exhibits lower DOI, reflecting light more scattered, resulting in blurry images.

Solution: Implement proper surface preparation techniques, including sanding and polishing, to achieve a smooth and uniform substrate surface for enhanced DOI.

-

Coating Thickness:

Issue: Variations in coating thickness can affect the uniformity of light reflection, leading to differences in DOI across the surface.

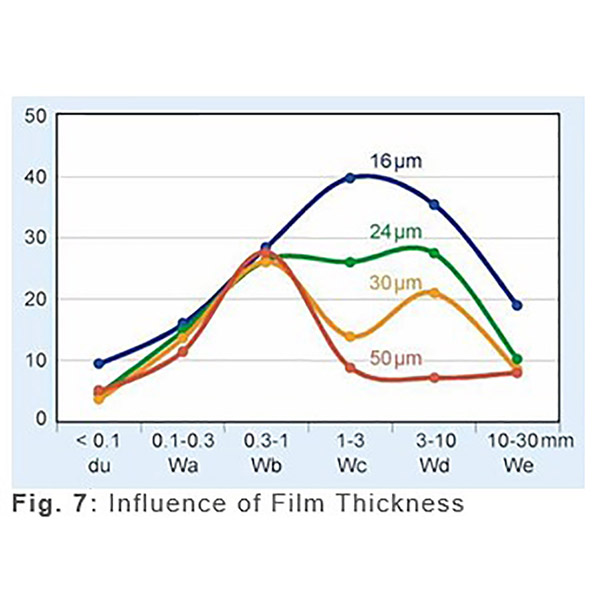

Solution: Control coating thickness through wet film thickness measurements, proper application techniques, and equipment calibration to ensure uniform film formation and consistent DOI across the surface. The structure spectrum can help determine the optimum film thickness. Increasing the clear coat thickness will improve flow and leveling, as shown by the decreasing Wc and Wd values (Fig. 7).

-

Curing Conditions:

Issue: Proper curing of the coating is crucial for achieving optimal DOI. Inadequate curing, by insufficient curing time, temperature, or position, can result in inadequate film formation, affecting surface smoothness and DOI.

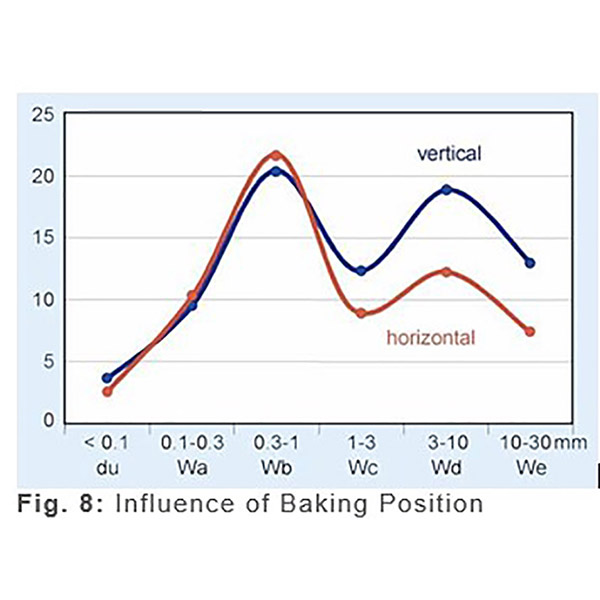

Solution: Follow manufacturer recommendations for curing time and temperature, ensuring adequate coating curing to achieve optimal film formation and DOI. For position, horizontal surfaces have a better flow and leveling behavior than vertical surfaces due to the influence of gravity, i.e., resulting in lower long wave values (Wc, Wd, We). The shorter waves are hardly influenced by the baking position. (Fig. 8)

-

Substrate Quality:

Issue: The condition and quality of the substrate can impact the final DOI, as imperfections or irregularities in the substrate can affect the evenness of the coating application and subsequent reflection.

Solution: Address any substrate defects or irregularities through proper surface preparation and repair techniques to minimize their impact on DOI.

Achieving a flawless surface appearance is essential in various industries, from automotive and furniture manufacturing to architectural coatings. Understanding the factors contributing to surface imperfections, such as orange peel and DOI, is crucial for effective troubleshooting and quality control. By addressing issues related to coating application, substrate preparation, and environmental conditions, manufacturers can optimize surface appearance, ensuring impeccable finishes that meet the highest aesthetic standards.